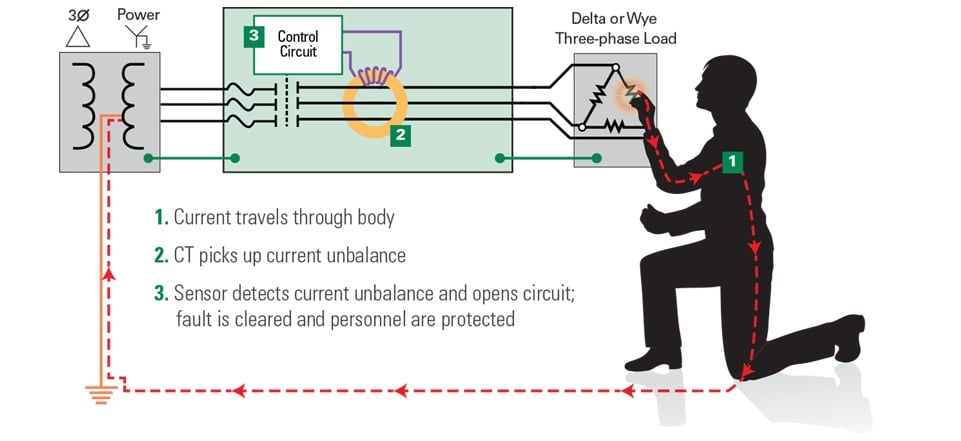

Industrial Shock Block® (ISB) is a personnel protection device designed to meet the requirements for special-purpose GFCIs defined by UL 943C. This standard outlines GFCI classes specifically designed for use in industrial facilities. Class C GFCIs are intended to be used on three-phase systems where the line-to line voltage is 480 V or less with a trip level of 20 mA, while Class D GFCIs are intended to be used on 600 V systems. The Industrial Shock Block includes an automatic self-test feature and is compliant to the UL 1998 Software in Programmable Components standard. The Shock Block is available as a Class A GFCI, allowing commercial kitchens, construction sites, and other non-dwelling units.

The SB6100 detects leakage current and interrupts the circuit, significantly reducing or eliminating the shock potential. One key part of the additional safety features is that the SB6100 also monitors the ground wire from the SB6100 to the load for continuity. If the wire is broken or becomes loose, the SB6100 will signal an alarm and interrupt power.

The combination of a wet environment, stainless steel equipment and conductive surfaces creates a situation where shock is more likely to occur. Equipment such as fryers, mixing equipment and electric ranges must be movable to meet sanitation standards, requiring plugs to be used. Flexible cords are prone to wear and tear over time, and worn insulation increases a worker’s risk for electrical shock. The National Electrical Code (NEC) 2017 version and later, now requires using a ground-fault circuit interrupter (GFCI), like the Littelfuse SB5000 Shock Block, for 208-volt three-phase applications up to 100 A. Its use on this equipment protects workers from electric shock and ensures both NEC, and health and sanitation code compliance.

The NEC 210.8[B] code requires GFCI protection for any plug and cord equipment that is 208 V, 3-phase and 100 A or below. Plug-in equipment such as dryers, mixers, cutting equipment, and conveyers fall into this category and must be protected with a GFCI. The Littelfuse SB5000 will meet this code requirement for your facility, but the protection doesn’t stop at 208 V. The Littelfuse Shock Block is also offered as Special Purpose GFCI protection all the way up to 600 V—personnel protection for all situations.

Special purpose GFCIs are required in industrial facilities and construction to meet the requirements defined by UL 943C. Class C GFCIs are intended to be used on three-phase systems where the line-to-line voltage is 480 V or less with a trip level of 20 mA, while Class D GFCIs are intended to be used on 600 V systems. The Industrial Shock Block includes an automatic self-test feature and is compliant to the UL 1998 Software in Programmable Components standard.

![]() SB6100 Datasheet

SB6100 Datasheet![]() SB5000 Datasheet

SB5000 Datasheet

Shock Block ground-fault protection has been recognized for years for its award-winning technology. Winner of an Academy Award® for Scientific and Engineering Achievement, the portable, rental Shock Block is designed to protect actors, film-crew and equipment on sets where water or moisture can create electrical hazards.

New technology blends a ground-fault circuit interrupter’s (GFCI’s) fast reaction time with proactive ground monitoring technology, which ensures a safe and reliable ground-fault path. This new pre-emptive approach originated from the special-purpose GFCI (SPGFCI) standard, but it is time to apply it to Class-A GFCIs.

How GFCIs Protect People From Electrical Hazards in Commercial Kitchens

To Decrease Fatalities and Injuries, Electrical Shock Safety Needs a Jolt of Change

Get insights on the reasoning behind why the electrical workers take unsafe actions and the challenges safety professionals and consultants experience when trying to keep these workers safe.

Littelfuse surveyed people who work on electrical equipment and asked them about their experiences, training, and protection methods. During this webcast, we will share key findings from the survey, misconceptions of electrical shock in the workplace, the importance of risk assessments, and areas to improve safety training.

The Industrial Shock-Block™ is a personnel protection device that effectively aids in safeguarding your people where equipment and water are present. The reliable performance and environmental considerations (humidity, ultraviolet, corrosion, and dust) of the SB6100 make it the perfect option for companies seeking high-quality protection for their employees. Below are a few examples of customers that discovered the many benefits of the Littelfuse Industrial Shock-Block™ SB6100.

A municipal water utility company, that supplies water to more than three million residents, wanted to protect its workers from shock hazards. The facility had two tanks the size of Olympic swimming pools containing 7-10 hp submersible pumps running on 600 V. Once or twice a year the tanks must be cleaned by hand, and workers enter while the water is still present and the pumps are running. The solution was the Littelfuse Industrial Shock-Block™ SB6100 EGFPD. The utility company installed the EGFPDs in the motor control centers that supply power to each pump. The EGFPDs operate like an industrial ground-fault circuit interrupter. If a device senses a ground fault above a trip setting, it will open the circuit very quickly to protect workers from shock.

Solution mining requires a constant supply of water. A large solution mining company has pump stations located near the water supply to pump the water in for processing. The water needs to be filtered before it is pumped to the mine so there is a filter screening the water intake. Even though a second filter is installed inside the pumping station, rocks, sand and debris still get into the station. Typically once a year, an employee must clean the debris out of the sump with the help of a submersible pump. Having a submersible pump running while the employee is cleaning leaves them at risk for electrical shock. The Industrial Shock-Block™ was the solution. They mounted the EGFPD on the wall inside the pumping station along the river bank. Because the Industrial Shock-Block™ is lightweight, the wall-mount installation among the electrical cabinets worked for this application. Now when a worker goes into the pumping station to clean the sump, they will be protected by the Industrial Shock-Block™.

A brick manufacturing plant in the Western United States processes clay into bricks and other building materials for residential and commercial projects. Part of this process involves wet saws that operate at high voltage (480 V) and it is a wet process. The company managers wanted to make sure operators were safe from electrical ground faults. The plant electrician discussed his concerns with a Littelfuse distributor in Salt Lake City, Utah, whose representative suggested the use of an equipment ground-fault protection device (EGFPD) from Littelfuse. The Industrial Shock-Block™ SB6100 was installed between the motor control center and the face-cut saws on a manufacturing line built in the 80s. It took a little experimentation to determine that 30 mA was the lowest setting that prevented nuisance tripping. If the device senses a ground fault at or above that threshold, it opens the circuit within 20 ms - fast enough to prevent worker injury or death from dangerous electrical shock.

Littelfuse, Inc. 6133 North River Road Suite 500, Rosemont, IL, 60018 USA, 773-628-1000 Copyright © 2025 Littelfuse, Inc.